Looking Ahead – Fenceline Monitoring

Posted: January 28th, 2025

Authors: Kyle H.

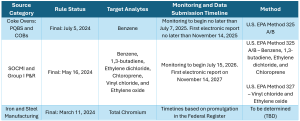

In 2024, the U.S. Environmental Protection Agency (U.S. EPA) finalized new fenceline monitoring requirements associated with amendments to Standards of Performance for New Stationary Sources (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) associated with the following source categories:

- Coke Ovens: Pushing, Quenching, and Battery Stacks (PQBS) and Coke Oven Batteries (COBs) – 40 CFR Part 63, Subpart L.

- Synthetic Organic Chemical Manufacturing Industry (SOCMI) and Group I Polymers and Resins (P&R) – 40 CFR Part 63, Subparts F, G, H, and I.

- Iron and Steel Manufacturing – 40 CFR Part 63, Subpart FFFFF.

In 2025, facilities subject to these rules should be preparing to comply with these new fenceline monitoring requirements. For Coke Ovens and SOCMI/Group I P&R, U.S. EPA promulgated monitoring requirements in the Federal Register and is in the process of doing the same for Iron and Steel Manufacturing once they designate a sampling and analysis method. The table below summarizes fenceline monitoring requirements for each category.

For details on the location and number of sampling sites, sampling and analysis, action levels, root cause and corrective actions, and reporting requirements, see ALL4’s 4 The Record Articles on Coke Oven Fenceline Monitoring and SOCMI/Group I P&R Fenceline Monitoring.

Conducting a pilot study ahead of the required fenceline monitoring implementation date is key to understanding how emissions from your facility impact fenceline concentrations and identifying potential areas of concern before implementing a comprehensive monitoring program. A secondary benefit of a pilot study is that it allows your facility to address the logistics of conducting a fenceline monitoring program by working with the sampling staff and the analytical laboratory to address sampling, analysis, and data interpretation. The pilot study could focus on smaller process areas or the site as a whole.

New Administration – What’s Next?

With the administration change, a common question asked is will these monitoring requirements remain in place or is there a possibility of a pause or reconsideration. In 2016, the same question was asked about fenceline monitoring as part of the Petroleum Refinery Sector Rule (40 CFR Part 63, Subpart CC) as monitoring requirements were finalized in 2015 (before an administration change).

In 2016, the Refinery fenceline monitoring requirements were not reconsidered or stayed. For the current fenceline monitoring requirements that were published in the Federal Register in mid-2024 for Coke Ovens and SOCMI/Group I P&R, it is uncertain whether U.S. EPA will reconsider them or if litigation will result in changes to the fenceline monitoring provisions; the possibility exists that the schedule will continue as outlined but it is still too early to tell. For the Iron and Steel Manufacturing Facilities, there is a potential for a delay since the fenceline monitoring methodology has not been published.

Two other rules that ALL4 is watching are the recently proposed updates to the Polyether Polyols NESHAP (40 CFR Part 63, Subpart PPP) and the Chemical Manufacturing Area Sources (CMAS) NESHAP (40 CFR Part 63, Subpart VVVVVV), which include fenceline monitoring similar to that included in the SOCMI and Group I P&R NESHAP. These rules may expand the universe of chemical facilities subject to federal fenceline monitoring requirements. Facilities subject to these rules should engage with their industry associations, as well as ALL4, to provide comments on the proposed changes and evaluate their impacts.

How can ALL4 help?

ALL4 closely tracks regulatory actions and developments from U.S. EPA and can help facilities interpret and address new requirements, and plan, prepare, and execute fenceline monitoring programs. We are currently assisting facilities with pilot studies and can support your needs as well. ALL4 can also evaluate data from ambient monitoring sites near your facility and how your facility may be impacting monitored concentrations. For more information, please contact Kyle Hunt at khunt@all4inc.com or Dustin Snare at dsnare@all4inc.com.